Glass Materials

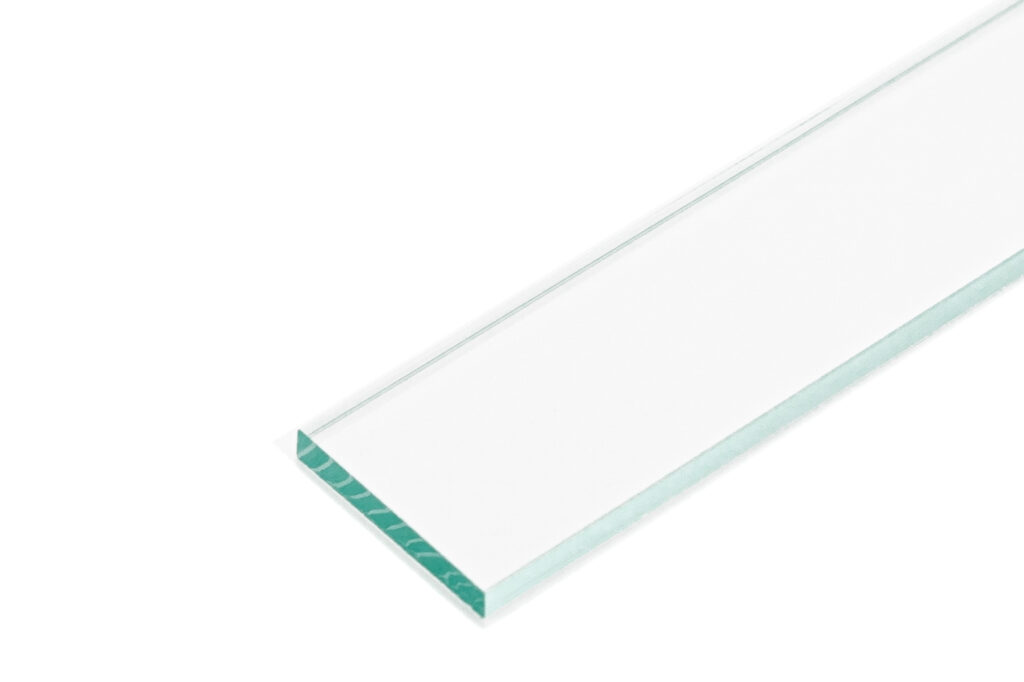

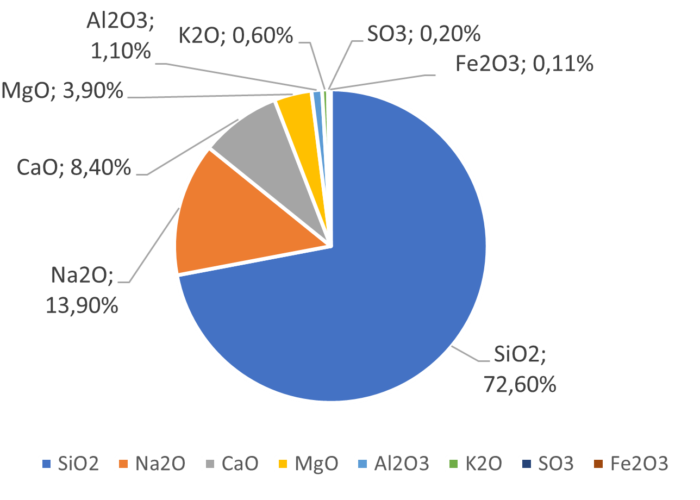

Soda Lime Glass

Glass relatively inexpensive and readily available, with a wide range of applications. Due to the high thermal expansion coefficient has a low resistance to sudden changes in temperature.

Flexural Strength

| Type | Flexural strength |

|---|---|

| Annealed | 41 MPa |

| Heat-Strengthened | 83 MPa |

| Toughened | 165 MPa |

Compressive Strength

| Type | Compressive strength |

|---|---|

| Annealed | 19 MPa |

| Heat-Strengthened | 39 MPa |

| Toughened | 77 MPa |

Glass Properties

| Description | Value |

|---|---|

| Density | 2500 kg/m^3 (@18°C) |

| Mohs hardness | 5-6 |

| Modulus of elasticity (Young’s) | 72 GPa |

| Shear modulus | 30 GPa |

| Poisson’s ratio | 0,23 |

| Coefficient of thermal stress | 0.62 MPa/°C |

| Thermal conductivity | 0,937 W/(mK) |

| Specific heat | 0,88 kJ/(kgK) |

| Coefficient of linear expansion | 8.3 x 10^-6°C |

| Index of refraction | 1.5 (@380 - 780 nm) |

| Softening point | 715°C |

| Annealing point | 548°C |

| Max. working temperature | - not toughened 110°C - toughened 150°C |

| Thermal shock Δ | - not toughened 50°C - toughened 118°C |

Robax

ROBAX® glass ceramic panels consist of a transparent glass ceramic material. Because of its material characteristics the product is designed for the use as thermal window in fireplaces.

Range of Application

This technical delivery specification applies to ROBAX® glass ceramic panels (delivery form: flat stock-size sheets, cut-to-size-panels and bent panels with or without decoration) for applications which require a low thermal expansion and transparency:

- electric, oil or gas stoves

- conventionally heated fireplaces and room heaters (wood, coal, pellets …)

Appearance

- Transparent, slightly coloured due to the material composition and production process

- Surface appearance: plane, slightly textured due to the production process

Mechanical Characteristics

| Description | Value |

|---|---|

| Density ƿ | approx. 2.6 g / cm^3 |

| Modulus of Elasticity (ASTM C-1259) E | approx. 93 x 103 MPa |

| Poisson’s Ratio (ASTM C-1259) μ | approx. 0.25 |

| Bending Strength (DIN EN 1288 part 5, R45) σbB | approx. 35 MPa |

Impact Resistance: The impact resistance of ROBAX® depends on the kind of installation, the size and thickness of the panel, the kind of impact, the geometry of the panel and especially here on the drilled holes and their position on the ROBAX® panel. Therefore information regarding the impact resistance can only be given with knowledge of the respective application (especially in combination with the technical standards regarding impact resistance that have to be met for single applications). Corresponding guideline values on request.

Thermal Characteristics

| Description | Value |

|---|---|

| Coefficient of Mean Linear Expansion (DIN ISO 51045-1, DIN ISO 7991) α (20 – 700°C) | (0 ± 0.5) x 10^-6 / K |

| Mean Specific Thermal Capacity cp (20 – 100°C) | approx. 0.8 x 10^3 J / (kg x K) |

| Thermal Conductivity (DIN 51936, ASTM E 1461-01) λ (90°C) | approx. 1.6 W / (m x K) |

Resistance to Temperature Differences (RTD): Resistance of the panel to temperature differences between heated zone and cold panel edge (room temperature). No cracking due to thermal stress at Tes, max1) ≤ 700°C.

Thermal Shock Resistance: Resistance of the panel to thermal shock when the hot panel is quenched with cold water (room temperature). No cracking due to thermal stress at Tes, max1) ≤ 700°C.

Temperature / Time Load Capacity: The temperature / time load capacity specifies the maximum permissible temperature for given load times for the fireplace panels, below which no cracking due to thermal stress occurs. The value pairs specified in the following table 2.1 are relevant to the practical use of the glass ceramic material as fireplace panel. The temperature values refer to the hottest point on the exterior side of the panel (Tes, max) because this temperature can be measured more easily and more reliably.

| Load temperature Tes, max | Load Time |

|---|---|

| 560°C (1040°F) | 5000 hr. |

| 610°C (1130°F) | 1000 hr. |

| 660°C (1220°F) | 100 hr. |

| 710°C (1310°F) | 10 hr. |

| 760°C (1400°F) | 5 hr. |

Table 2.1: Temperature / time load capacity for ROBAX fireplace panels.

1) Tes, max: Maximum temperature on the exterior side of the panel, that means the reverse side of the heat source, at the hottest point

Note: for ROBAX® fireplace panels the temperature / time load capacity specified in table 2.1 must be maintained. It must be ensured that this temperature / time load capacity is not exceeded during use, to prevent cracking due to thermal stress.

The temperature / time load data for even temperature distributions within an entire glass ceramic panel (e.g. homogeneous heating conditions in a testing furnace) are given in table 2.2. This data is to be seen purely as characteristic data for the glass ceramic material itself. It is not typical for use of the ROBAX® glass ceramic material as fireplace panels, which have a temperature distribution totally different from evenness. The temperatures refer to the homogeneous heating of the ROBAX® panel (Thom).

| Load temperature Tes, max | Load Time |

|---|---|

| 700°C (1292°F) | 6000 hr. |

| 750°C (1382°F) | 750 hr. |

| 775°C (1427°F) | 275 hr. |

| 800°C (1472°F) | 100 hr. |

| 825°C (1517°F) | 35 hr. |

Table 2.1: Temperature / time load capacity for ROBAX fireplace panels.

2) Thom: Homogenous temperature, i.e. material temperature under homogeneous heating conditions

Chemical Characteristics of Base Material

| Description | Value |

|---|---|

| Acid Resistance (DIN 12116) S | at least class S2 |

| Alkaline Resistance (ISO 695) A | at least class A1 |

| Hydrolytic Class (DIN ISO 719) HGB class | HGB 1 |

Change of Surface due to Use: ROBAX® has a good resistance against chemical surface attack. In isolated cases and under special critical conditions, e.g. aggressive exhaust gases (acidification at high temperatures) changes of the surface may occur. For such applications practice tests have to be carried out before being used.

General Dimensional Tolerances and Material Characteristics

Material Characteristics: Visual inspection in the normal installation position without visual aids and illumination of approx. 800 Lux when viewed from a minimum distance of 1 m. The inspection shall be executed with a background in the colour of fireclay bricks: Light ivory RAL-1015.

Bubbles: Bubbles are gaseous inclusions within the glass ceramic material. Closed bubbles can appear as low-spots on the surface depending on their size and position within the glass. Open bubbles are open towards the panel surface and are not permissible if bigger than 1 mm. The production of material totally free of bubbles is not possible due to the production process. Table 3.2 contains the permissible number of closed bubbles in dependence of their length and the panel size.

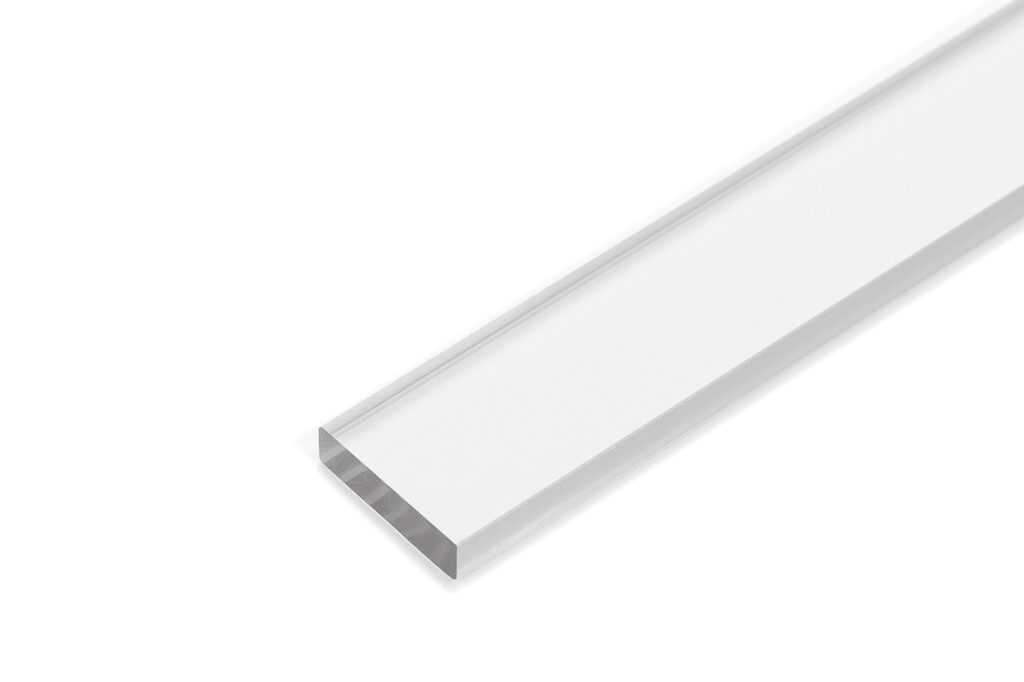

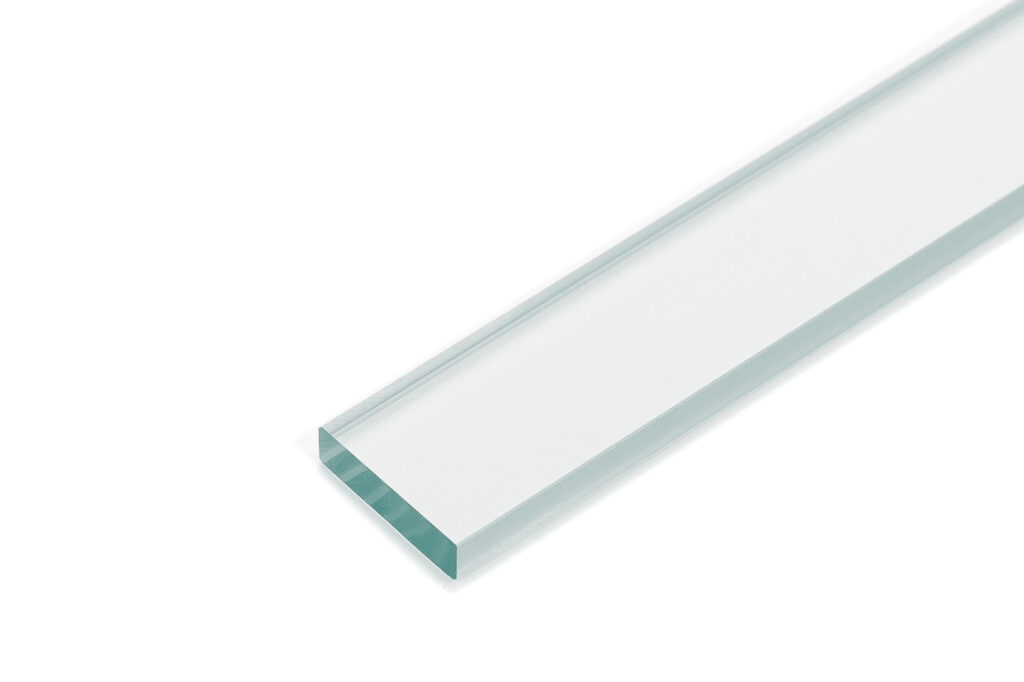

Fused Quartz Glass

Clear fused quartz glass is a unique material with an unrivalled combination of purity, high temperature resistance, thermal shock resistance, high electrical insulation, optical transparency and chemical inertness.

Mechanical Characteristics

| Description | Value |

|---|---|

| Density | 2.20 x 103 Kg/m^3 |

| Youngs Modulus | 74 x 106 KN/m^2 |

| Rigidity Modulus | 32 x 106 KN/m^2 |

| Compresive Strength | 20 x 106 KN/m^2 |

| Tensile Strength | 70 x 103 KN/m^2 |

| Shear Strength | 70 x 103 KN/m^2 |

| Moh’s Hardness | 6 |

Electrical Characteristics

| Description | Value |

|---|---|

| Electrical Resistivity | - 2 x 10^19 ohm cm at 20°C - 2 x 10^6 ohm cm at 800°C |

| Dielectric Strength | - 10KV/mm at 20°C - 2.5KV/mm at 500°C |

Thermal Characteristics

| Description | Value |

|---|---|

| Strain Point | 1385°K |

| Annealing Point | 1455°K |

| Softening Point | 1853°K |

| Coefficient of Expansion | 0.52 x 10^-6 per °C |

| Continuous Operating Temp. | 1050°C |

Optical Characteristics

| Description | Value |

|---|---|

| Useful Optical Range | Synthetic 180 - 2000nm Natural 275 - 2000nm |

| Refractive Index nD (589 nm | 1.458 |

Chemical Characteristics

SiO2 Content – 99.995%

Total Metallic Impurities – 10ppm (Typical)

Chemical Inertness: fused quartz does not react with acids with the exception of hydrofluoric and at high temperatures phosphoric. There is a slow reaction with caustic alkalies at normal temperatures. There is no reaction with water and steam at moderate temperatures and pressures.

Ceramic Glass

Alumina ceramic substrate has lots of advantages, it has good thermal conductivity, stable insulation, thermal shock resistance, wear resistance, Anti-acid and Anti-alkali etc. Can be used in thick film hybrid integrated circuits HTC, LED ceramic heat sink, power modules, semiconductor devices and other fields. Commonly used ceramic substrates are Al2O3, AlN, SiC, BeO, BN, ZrO2 and glass ceramics. Although the thermal conductivity of Al2O3 ceramic substrate is not high (20W/m.K), it is the most widely used ceramic substrate because of its relatively simple production process, low cost and low price.

Main Performance Parameters

| Description | Value |

|---|---|

| Purity | Alumina(Al2O3) 96%, 99% and 99.7% |

| Density (g/cm^3) | >3.75 |

| Thermal conductivity (w/m.k) | >24 |

| Thermal expansion (x10 ^-6 / ℃) | 6.5~7.5(20~300℃) 6.5~8.0(300~800℃) |

| Dielectric Strength (Kv/mm) | >17 |

| Dielectric Constant (at 1MHZ) | 9~10 |

| Loss tangent (x10 -4^ @1MHZ) | 4 |

| Flexural strength (N/mm^2 ) | >350 Mpa |

| Water absorption | 0 % |

D263 Glass

D 263® T eco thin glass is a clear borosilicate glass that has a high chemical resistance and is produced by a SCHOTT specific down-draw method. It is available in a variety of thicknesses ranging from 0.03 mm to 1.1 mm. D 263® T eco borosilicate glass is available in standard stock size sheets or can be custom cut into round or square shapes. D 263® T eco thin glass is used as substrate glass for coatings or as replacement for plastic for applications in the automotive and electronics industries. D 263® T eco is manufactured with eco-friendly refining agents.

Main Performance Parameters

| Description | Value |

|---|---|

| Surface roughness | < 1 nm RMS |

| Thicknesses | 0.03 mm up to 1.1 mm |

| Luminous transmittance τvD65 (d = 1.1 mm) | 91.7 % |

| Coefficient of mean linear thermal expansion α (20 °C; 300 °C) (static measurement) | 7.2 x 10^–6 K^–1 |

| Transformation temperature Tg | 557 °C |

| Dielectric constant εr at 1MHz | 6.7 |

| Refractive index nD | 1.5230 |

| Refractive index ne | 1.5255 ± 0.0015 |

| Density ρ (annealed at 40 °C/h) | 2.51 g/cm^3 |

| Intensity of α-radiation | < 0.2 counts (h · cm^2) |

Borofloat Glass

Borofloat glass has outstanding thermal resistance, exceptionally high transparency and high chemical durability, as well as excellent mechanical strength.

Thermal Properties

| Description | Value |

|---|---|

| Coefficient of Linear Thermal Expansion (C.T.E.) α(20–300 °C) | 3.25 x 10^-6 K^-1 |

| Transformation temperature Tg | 525 °C |

| Annealing Point (1013 dPas) | 560 °C |

| LITTLETON temperature/Softening point (107.6 dPas) | 820 °C |

| Thermal conductivity λ (90 °C) | 1.2 W/(m·K) |

| Specific heat capacity cp (20 –100 °C) | 0.83 kJ/(kg·K) |

| Maximum Operating Temperature | For short-term usage (< 10 h) 500 °C For long-term usage (≥ 10 h) 450 °C |

Optical Properties

| Description | Value |

|---|---|

| Refraction index (nd (λ587.6 nm)) | 1.471 |

| Dispersion (nF - nC) | 71.4 x 10^-4 |

| Low inherent fluorescence and solarisation tendency | - |

Chemical Durability

| Description | Value |

|---|---|

| Hydrolytic resistance | (according to ISO 719 / DIN 12 111) HGB 1 (according to ISO 720) HGA 1 |

| Acid resistance (according to ISO 1776 / DIN 12 116) | 1 |

| Alkali resistance (according to ISO 695 / DIN 52 322) | 2 |

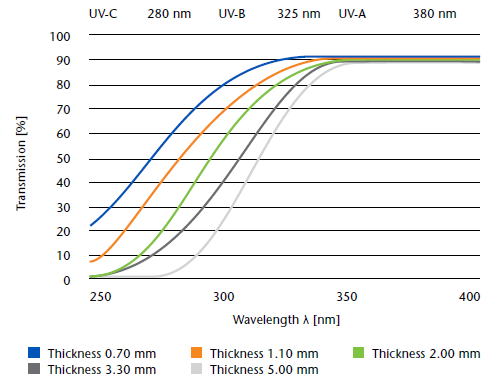

Transmission in UV range

Mechanical Properties

| Description | Value |

|---|---|

| Density ƿ (25 °C) | 2.23 g/cm^3 |

| Young’s Modulus Ε (according to DIN 13316) | 64 kN/mm^2 |

| Poisson’s Ratio μ (according to DIN 13316) | 0.2 |

| Knoop Hardness 0.1/20 (according to ISO 9385) | 480 |

| Bending Strength σ (according to DIN 52292 T 1) | 25 MPa |

Electrical Properties

| Description | Value |

|---|---|

| Dielectric Constant Ɛ (1 MHz & 25 °C) | 4.6 |

| Loss Tangent tan δ (1 MHz & 25 °C) | 37 x 10^-4 |

| Specific Volume Resistance in Ω cm | log ƿ 250°C 8.0 log ƿ 350°C 6.5 |

Black Glass NG1

NG1 Black glass is unique glass which perfectly fits for applications where reflective reading heads are used. Glass itself absorbs light pretty well and doesn’t require any additional coating on the back

Main Performance Parameters

| Description | Value |

|---|---|

| Reflection factor Pd | 0.918 |

| Reference thickness d [mm] | 1 |

| Spectral values guaranteed τ i (546nm) | < 0.0001 |

| Refractive Index n nd (587.6 nm) | 1520 |

| Density ρ [g/cm^3 ] | 2.47 |

| Bubble content | Bubble class: 2 |

| Chemical Resistance | FR class 1.0 SR class 2.2 AR class 1.0 |

| Transformation temperature Tg [°C] | 471 |

| Thermal expansion | α-30/+70°C [10^-6/K] 6.6 α 20/300°C [10^-6/K] 7.2 α 20/200°C [10^-6/K] |